Design

Home / Design

Injection Moulding DESIGN

Plastics 2000 advocates that good design will save you money and the end product should exceed your expectations.

Designing a complex plastic object requires much consideration – you should think carefully about its purpose, how it will interlock with other components and the amount of pressure it will sustain through normal use. Additionally, think about the thickness of the product required, its flexibility or rigidity, does it need to taper and can you consider a ribbed design to save on material costs and weight?

The expert Plastics 2000 Team is here to help and advise you with these decisions; with our vast experience we can assist you in choosing the perfect design and material to manufacture the perfect product for your needs.

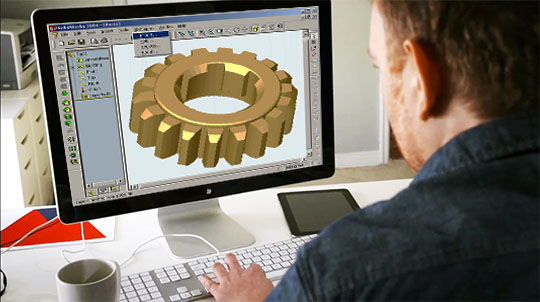

COMPUTER AIDED DESIGN

Plastics 2000 particularly welcomes customers who have already worked through the design process and have purchased their own tool to manufacture their product.

However, for those with an economically viable concept, Plastics 2000 can recommend a qualified Computer Aided Design (CAD) technician. The use of CAD is advantageous in allowing the conceptual design to be remodelled and virtually tested; this reduces the waste of time and materials that would be traditionally used in prototypes. The CAD solid modelling not only shows how the finished product will look, but the software can simulate how your design will work in the real world.

The use of CAD is essential in designing the tool required to mould an item. When the concept is agreed and finalised Plastics 2000 will assist you in sending your design to a Tool Maker for production. Upon receipt of the finished tool, Plastics 2000 can immediately begin production, package and distribute your product.